On-Site Expertise: Alloy Verification, Corrosion Studies, and Coating Inspections

At OSE Services, we specialize in alloy verification, coating inspections, and corrosion studies. Our mission is to provide reliable and precise analyses to help our clients ensure the quality of their products and prevent material failures. We are committed to delivering high-quality service, adhering to strict ethical standards, and continuously adapting to technological advancements.

Materials and Surfaces: Characterization and Analysis of Alloys and Coatings

From design to market launch of a product with metallic components, you face several issues, including:

- Control of raw materials

- Performance of surface treatments

To assist you in resolving these issues, support from a reliable laboratory with high technical added value enables you to better understand the changes in the metallurgical sector and increase efficiency in your activities.

OSE Services On-Site and Laboratory Interventions

OSE Services offers on-site and laboratory interventions for industrial companies, technical experts, and judicial authorities in metallurgy and steel analysis.

Analyses On-Site and in the Laboratory

- Alloy Grade Control

- Surface Analyses

- Metal Powder Analysis

- Hardness Analysis

- Identification of Unknown Alloys On-Site

Expertise

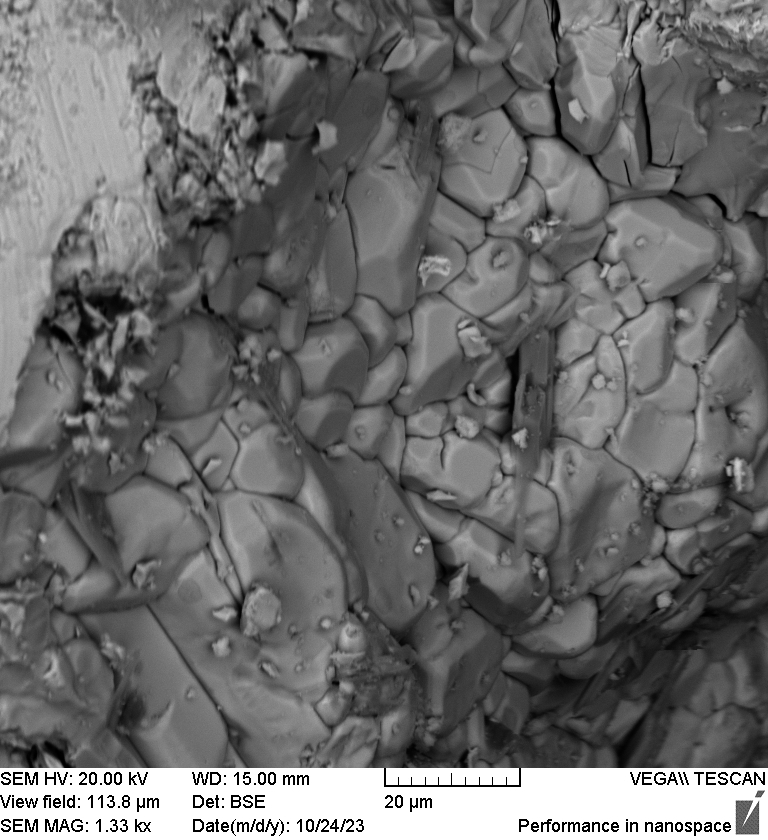

Our metallurgy and steel expertise includes:

- Failure Analysis

- Microstructure Studies

- Material/Fluid Compatibility Studies

- Metallographic Examination

Alloy Verification

Methods Used

Alloy verification is one of our specialties. We use advanced techniques such as X-ray fluorescence spectrometry (XRF) and inductively coupled plasma mass spectrometry (ICP-MS) to analyze the composition of metallic alloys. These methods allow us to accurately detect and quantify the elements present in a sample.

Applications

Our alloy verification services are essential for sectors such as aerospace, automotive, shipbuilding, and energy production. By verifying the composition of materials, we help prevent potential failures due to the use of inappropriate or substandard materials.

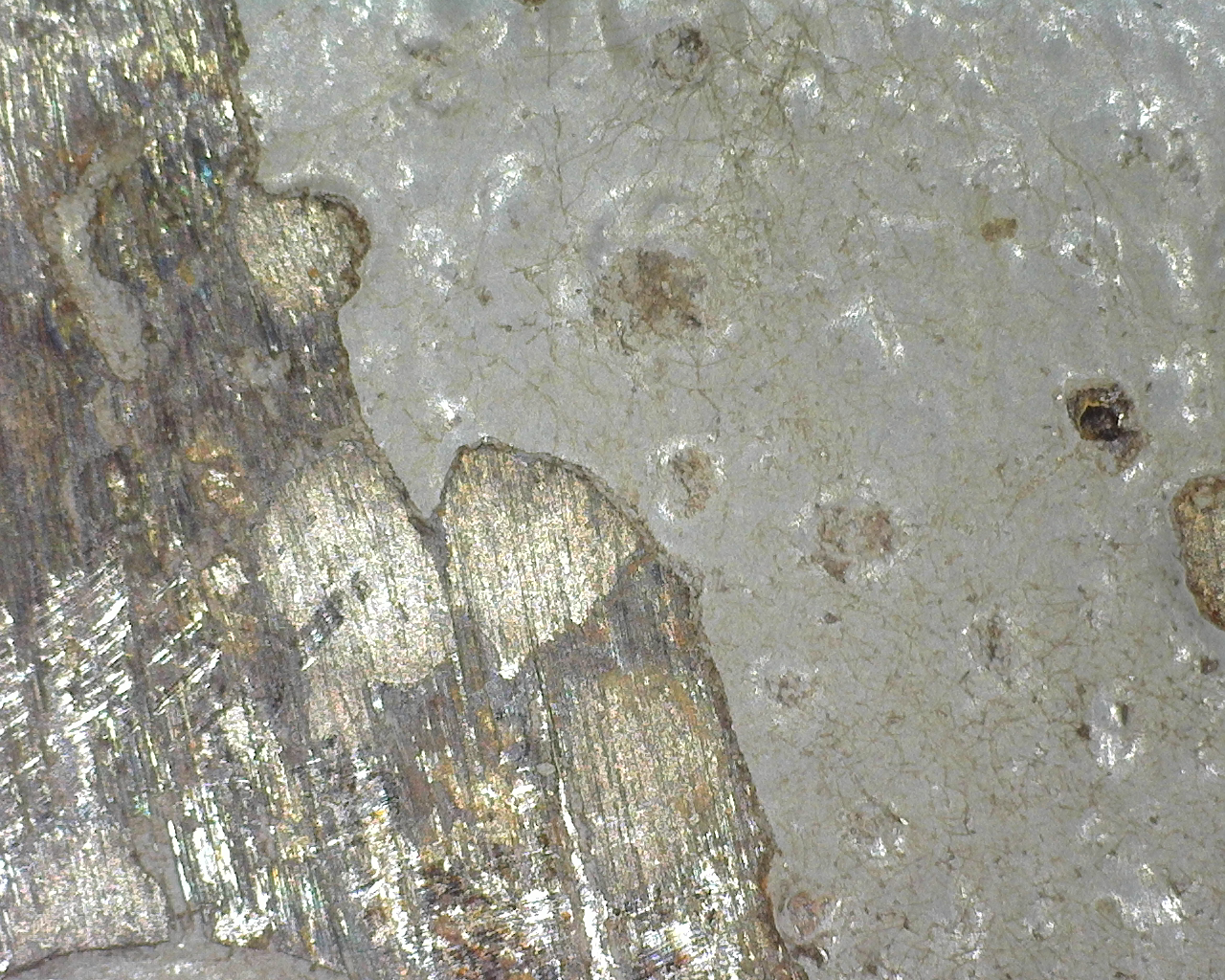

Coating Studies

Different Types of Coatings

Anticorrosion coatings are crucial for protecting metallic materials against degradation caused by corrosive environments. Here is an overview of the different types of commonly used anticorrosion coatings:

- Paints and Organic Coatings

- Metallic Coatings

- Galvanization

- Inorganic Coatings

- Specialized Polymer-Based Coatings

- Anodization

We ensure that coatings meet specifications and are not in environments that accelerate degradation.

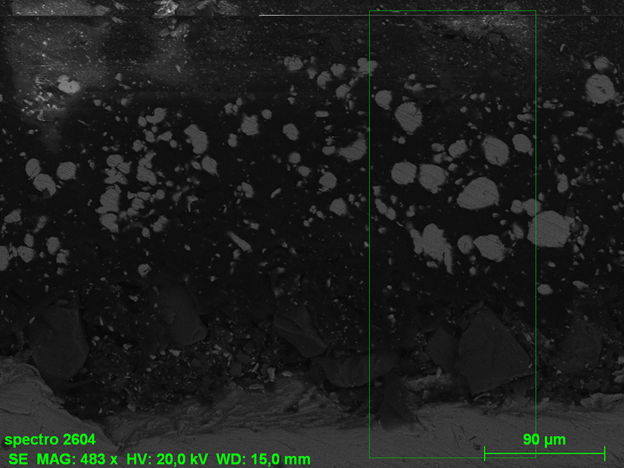

Study Techniques

Our on-site experts and laboratory use various techniques to study coatings, including:

- Digital optical microscopy

- Scanning electron microscopy (SEM)

- Fourier-transform infrared spectrometry (FTIR)

- X-ray fluorescence spectrometry (XRF)

- X-ray diffraction (XRD) analysis

- Pyrolysis GC/MS

- X-ray tomography

These methods allow us to verify the nature and thickness of the coating layer, characterize coating products, and evaluate the effectiveness of protective coatings.

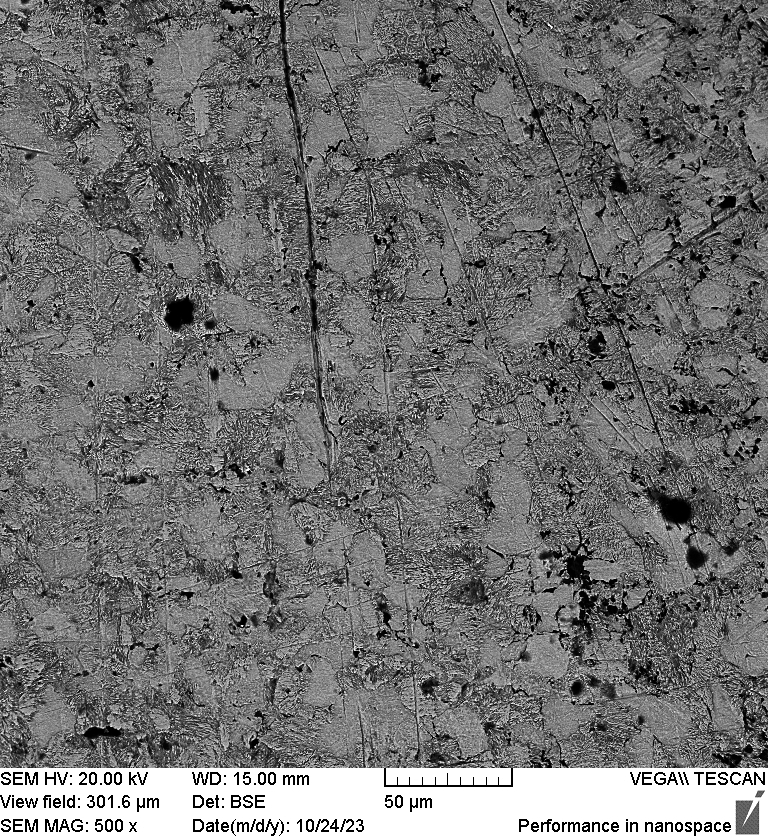

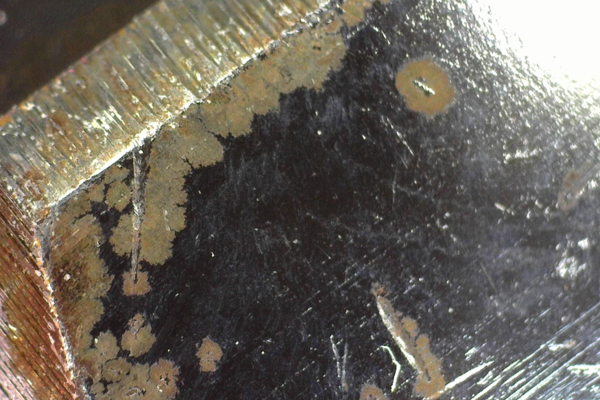

Corrosion Studies

Importance of Corrosion

Corrosion is a natural phenomenon that can cause significant damage to metallic structures, resulting in high repair and maintenance costs. Understanding the mechanisms of corrosion and ways to prevent it is crucial for extending the lifespan of equipment and infrastructures.

Study Techniques

Our laboratory uses several techniques to study corrosion, including:

- Scanning electron microscopy (SEM)

- Electrochemical tests

- X-ray diffraction (XRD) analysis

These methods enable us to understand corrosion mechanisms, characterize corrosion products, and evaluate the effectiveness of protective coatings.

On-Site Analyses

Need for On-Site Analyses

Some situations require immediate, on-site analyses. Our on-site analysis service is designed to meet these needs, providing quick and precise evaluations directly in the field. This is particularly useful in industries where time is a critical factor, such as oil and gas production, construction, and infrastructure maintenance.

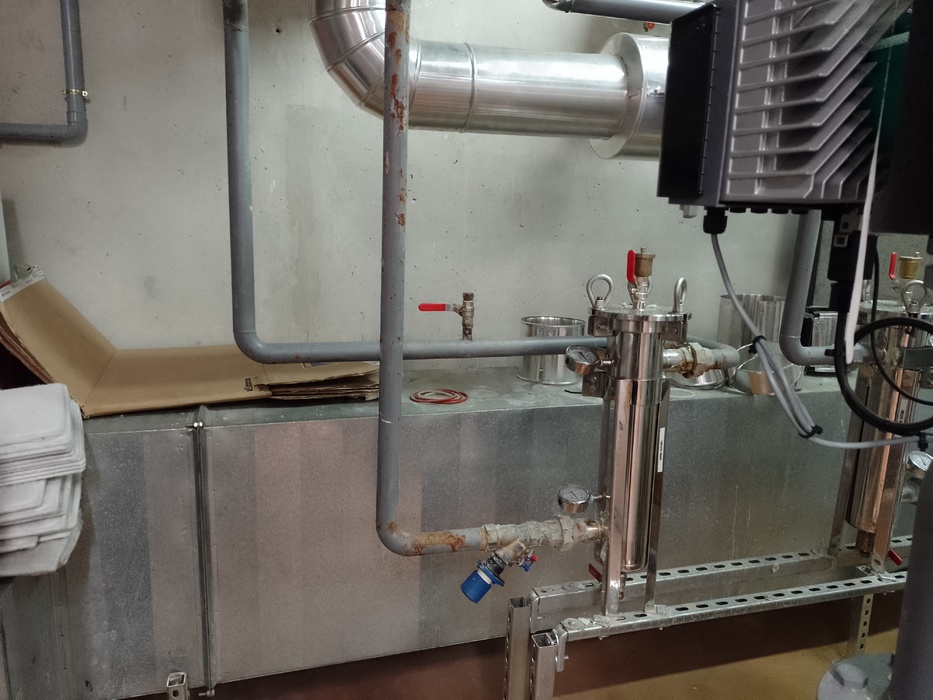

Equipment and Skills

We have state-of-the-art portable equipment for on-site analyses, including:

- Portable XRF analyzers

- Hardness testers

- Coating thickness measurement devices

Our highly skilled technicians and engineers can provide immediate results and on-site recommendations, helping to make rapid and informed decisions.

Case Studies and Achievements

Case Study 1: Alloy Verification for Support Cables

In a maintenance project for a nuclear power plant, our laboratory was tasked with verifying the alloys used in critical piping. Through precise analyses, we identified non-compliant components, allowing the client to replace defective parts before they caused major issues.

Case Study 2: Corrosion Analysis in a Heat Exchanger

A food industry company requested our services to study corrosion in their heat exchanger. Using electrochemical techniques, XRF and SEM-EDX analyses, as well as XRD analyses, we identified the causes of corrosion and proposed solutions to improve material resistance.

Case Study 3: Coating Analysis of Handrails

A construction company commissioned us to determine the cause of corrosion in residential building handrails. After on-site studies and analyses, we found that the applied coatings lacked any anticorrosion agents. Verification against the specifications revealed a lack of compliance in all handrail coatings.

And many more on our blog OSE INDUSTRIES.

The laboratory for alloy verification and corrosion studies plays a crucial role in ensuring the quality and durability of metallic materials. Our diverse services, ranging from alloy verification to corrosion studies and on-site analyses, offer comprehensive solutions to meet our clients' needs. By combining technical expertise and innovation, we strive to provide reliable and precise analyses to support our clients' success in various industries!